Semiconductor testing services

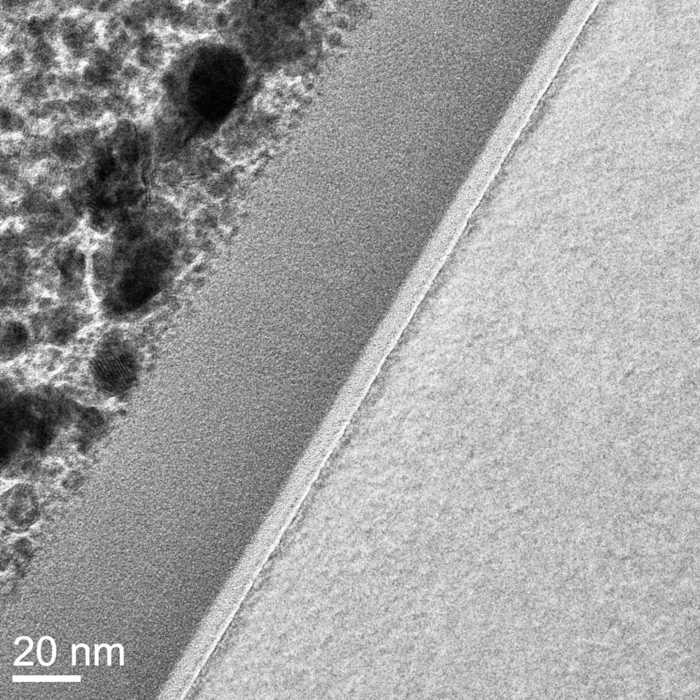

Imaging services

We offer several techniques for high-resolution imaging of semiconductor devices and components, including the following:

Several additional detectors are available for electron microscopy, including EDX for simultaneous elemental analysis and EBSD for visualizing crystal structures. Cross-sectional analysis is possible with FIB and BIB sample preparation.

SEM-EDX imaging

AFM surface imaging

HR-TEM imaging

STEM-EDX

SEM imaging

Focused ion beam (FIB) preparation

Scanning acoustic microscopy (C-SAM)

X-ray computed tomography (micro and nano CT scan)

Prices excluding VAT.

Elemental composition analysis

Measurlabs offers several options for determining the elemental composition of thin films and wafers, both at the surface and as a function of depth. Some of the available analysis techniques include the following:

Tof-ERDA for detecting all elements and different isotopes of hydrogen

SIMS for detecting trace amounts (ppm to ppb level) of impurities on the surface and at different depths

GD-OES for fast quantitative depth profiling without the need for a vacuum chamber – capable of detecting light elements

VPD-ICP-MS for determining trace metal contamination on the sample surface

ToF-ERDA measurement

SIMS measurement

GD-OES measurement

VPD ICP-MS

Prices excluding VAT.

Determination of physical characteristics

We provide a range of methods for determining the thickness, roughness, density, and other physical properties of thin films and wafers used in semiconductor development. Some of the testing options include the following:

Roughness measurements with atomic force microscopy and optical profilometry

Thickness measurements with X-ray reflectometry and ellipsometry

Crystal structure determination with GI-XRD

AFM surface roughness measurement

XRR of thin films or coatings

GI-XRD of thin films

Ellipsometry measurement

Prices excluding VAT.

Mechanical and thermal testing

Our service selection includes various measurements for assessing the durability of microelectronics, PCBs, electrical appliances, and components under specified mechanical stresses and temperature conditions. These include the following tests:

The above are just a few examples of our capabilities, so do not hesitate to ask about other tests.

One partner for all your semiconductor testing needs

When you order semiconductor testing services from Measurlabs, you will get access to a wide range of techniques in one place, reliable and clear results, and support from skilled experts, who will take ownership of your current and future testing projects with us. Do not hesitate to contact us to learn more.

Request a quote

Fill in the form, and we'll reply in one business day.

Have questions or need help? Email us at info@measurlabs.com or call our sales team.