Testing of engineering plastics

Chemical characterization

Our chemical characterization services for engineering plastics and chemicals used in their production include several advanced GPC/SEC methods, as well as NMR, FTIR, and Raman spectroscopy. Examples of popular measurements and their applications include:

Polymer characterization by NMR to identify polymers and evaluate their purity or contamination levels

Polymer characterization by py-GC-MS to determine polymer types by their decomposition products

Raman and FTIR analyses to identify specific chemical groups within the polymer structure

For molecular weight determination, we offer several GPC/SEC techniques suitable for different types of polymers. You can find out more about these analyses through the links below.

Molecular weight of polymers with GPC/SEC-RI

Molecular weight of polymers with GPC/SEC-MALS

Molecular weight of polypropylene with GPC/SEC at high temperatures

Molecular weight of UHMW polymers with AF4-MALS

Prices excluding VAT.

Thermal analysis

We offer several characterization techniques to ensure that engineering plastics meet application-specific criteria for thermal properties, indicating their ability to maintain a high degree of performance at low and high temperatures. The following are examples of our most commonly requested services in this area:

Differential scanning calorimetry (DSC), yielding information on transition temperatures and enthalpy changes

Thermogravimetric analysis (TGA), providing data on phase transitions, decomposition behavior, and solid-gas reactions

Thermomechanical analysis (TMA), measuring dimensional changes and mechanical properties in response to temperature variations

Dynamic mechanical analysis (DMA), determining changes in viscoelastic properties as a function of temperature and frequency of applied stress or strain

We also provide analyses with less widely available techniques, such as vacuum TGA, where thermal properties are studied under low-pressure conditions. Do not hesitate to contact our experts for more information or a tailored quote.

Thermal characterization with DSC

Thermogravimetric analysis (TGA)

Thermal conductivity of plastics - Transient plane source (TPS) method

Oxidation induction time (OIT) measurement

Prices excluding VAT.

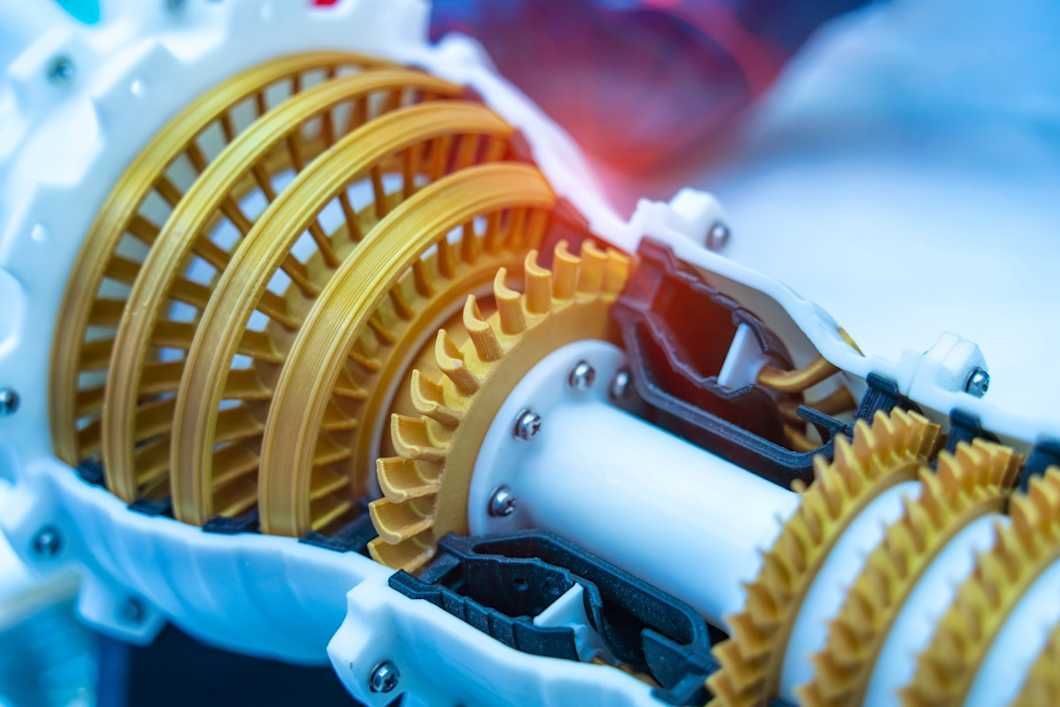

Electrical properties

Electrical testing is crucial when engineering plastics are used in electrical applications, such as protective casings, cable sheathing, or film capacitors. Our service selection contains the following standardized electrical tests for plastics:

Dielectric strength according to IEC 60243-1 or ASTM D149

Dielectric constant (i.e., relative permittivity) according to IEC 62631-2-1 or ASTM D150

Surface and volume resistivity according to IEC 62631-3-1 and IEC 62631-3-2

Comparative tracking index (CTI) according to IEC 60112

Electromagnetic interference (EMI) shielding effectiveness according to IEEE-299

Upon request, the dielectric strength and resistivity tests can be conducted at cryogenic or elevated temperatures.

Fire behavior

Flammability testing according to the UL 94 rating system is often required when engineering plastics are used in applications where they must exhibit a significant degree of fire resistance, such as construction products and electronic devices. We offer the following UL 94 tests for plastic flammability rating:

Horizontal burning test for HB classification of solid and cellular plastics

50 W vertical burning test for V2, V1, and V0 classifications

500 W vertical burning test for 5VB and 5VA classifications

Horizontal burning test for foamed plastics for HBF, HF-2, and HF-1 classifications

Other fire tests are also available for polymer-based construction materials and components used in specific high-risk environments, such as on trains, ships, and buses. The links below provide more information on some of these tests.

ISO 5659-2: Smoke generation – Optical density by a single-chamber test

IMO 2010 FTP Code Part 2 – Smoke and toxicity test

EN ISO 9239-1: Reaction to fire tests for flooring

EN ISO 11925-2: Ignitability with a small flame

Prices excluding VAT.

Ask for an offer

Fill in the form, and we'll reply in one business day.

Have questions or need help? Email us at info@measurlabs.com or call our sales team.