Electron microscopy (EM) can be used to visually analyze features that are too small to observe with an optical microscope. Electron microscopes use electrons, instead of visible light, to illuminate the samples. Electrons have a smaller wavelength than visible light and therefore allow higher-resolution imaging of features as small as 0.1 nm.

The most commonly used EM techniques are scanning electron microscopy (SEM) and transmission electron microscopy (TEM). SEM imaging enables visualization of a sample’s surface by scanning the sample with an electron beam, whereas imaging samples with TEM involves the transmission of electrons through a sample, allowing the internal structure to be visualized. While both techniques are used for high-resolution imaging, their applications and sample preparation requirements differ.

SEM and TEM have several commercial and research applications, including:

Materials QC and failure analysis

Analysis of biological specimens

Similarities and differences between SEM and TEM

Both SEM and TEM allow high-detail imaging of various materials, but there are differences in sample requirements, sample preparation procedures, and the type of information one can get from the sample. Resolution is also a key difference; while SEM can be practically used to image features from 1 cm to 10-30 nanometers, TEM can be used to image features down to 0.1 nm. For observing details above the micrometer size range, optical microscopy is typically a more cost-effective option, although it does have some limitations, such as a narrow field of depth.

As SEM is a tool for surface visualization, there are no limitations on sample thickness, as long as samples are small enough to be mounted on the sample holder. Non-conducting samples can suffer from a charge buildup during imaging, which can lead to imaging artifacts. This is resolved by coating the samples with a thin layer of a conducting material beforehand. Typical coating involves sputtering with gold, gold-palladium, platinum, or carbon. Other ways to prevent charging include ensuring that the sample has good contact with the sample stub, for example by using conductive two-sided carbon tape or silver glue. For a normal high-vacuum SEM, samples should be completely dry, but modern cryo-SEM and environmental SEM techniques make it possible to also image wet samples.

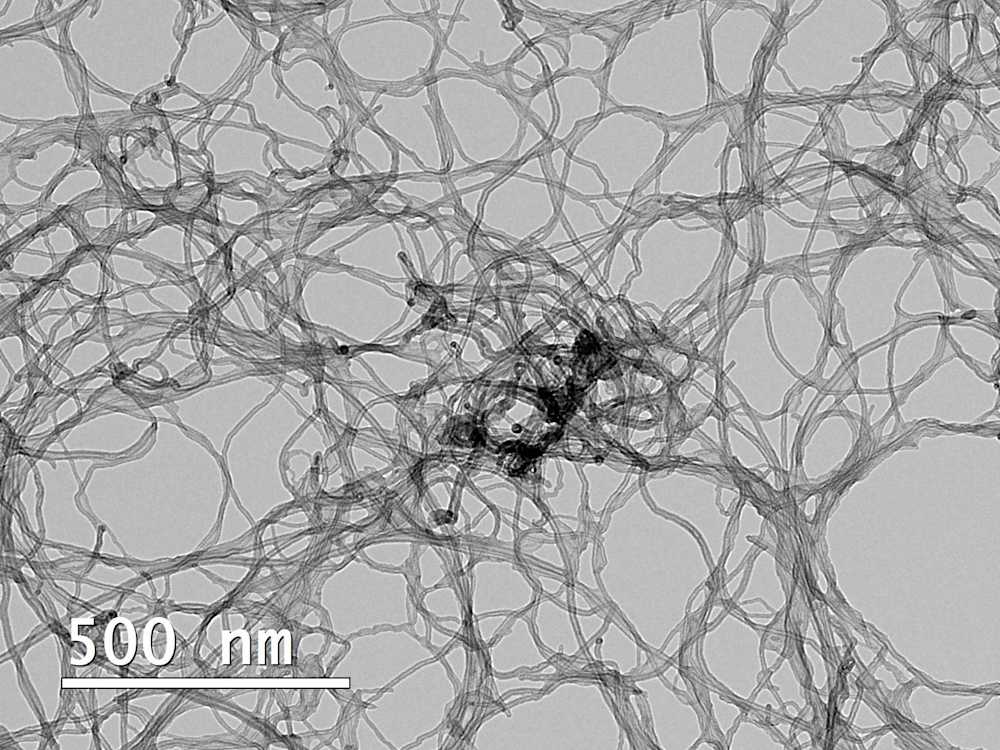

As TEM transmits a beam of electrons through the sample to produce an image of its inner structure and shape, samples need to be sufficiently thin for the beam to pass through them. Usually, the sample needs to be well below 100 nm thick to have the beam pass through it. Larger particles or materials can be imaged too, but they show as completely dark regions in the image, and only the shape can be determined. Thin samples can be obtained with advanced cutting techniques, such as focused ion beam (FIB) preparation or microtomy.

Although neither technique is destructive in principle, in some cases SEM samples need to be treated for better imaging and TEM requires the preparation of ultrathin sections. Therefore, the return of samples is not always guaranteed.

Both SEM and TEM can be used in combination with energy-dispersive X-ray spectroscopy (EDX), which allows the identification of the chemical elements in the sample. However, EDX gives no information on the chemical bonding, oxidation states, or valency of the elements seen. These can be obtained with electron energy loss spectroscopy (EELS), which can be combined with TEM, or by using other techniques.

Table 1: Key differences between SEM and TEM

| SEM | TEM |

Information obtained | Surface imaging, including texture & 3D features | Internal features of thin samples, morphology |

Type of detection | Secondary electrons or backscattered electrons are detected from above the sample | Electrons transmitted through the sample are detected |

Specimen thickness | Anything that fits the chamber, larger samples more prone to charging | Less than 1 mm to fit in the microscope, less than 100 nm to see the internal structure |

Maximum magnification | Up to 1 – 2 million times | More than 50 million times |

Maximum resolution | 10 nm* | 0.1 nm* |

Maximum field of view (FOV) | Large | Small |

Wet or dry samples? | Dry for normal SEM, wet for environmental SEM | Dry for normal TEM, wet vitrified samples for cryo-TEM |

Sample preparation | Mount the sample on a sample stub using conductive tape or silver glue | Depending on the sample; drop-casting followed by wicking extra liquid out (nanoparticles), cross-sectional FIB, microtomy, solvent casting |

EDX-compatible | Yes | Yes |

EELS-compatible | No | Yes |

Crystallography (electron diffraction) | Yes | Yes |

* These are typical values, the maximum resolution depends on the instrument.

Ideal applications of SEM

SEM is extremely useful for looking at the surface of a sample. The uses include visualizing and studying the surface of semiconductors, as well as QC processes in food and beverage packaging. SEM can also be used for particle size distribution analysis, particularly where samples are irregular in shape or unsuitable for laser diffraction (LD) or dynamic light scattering (DLS). The key advantages of SEM are that:

It allows high-magnification imaging of a surface where structural defects or impurities would cause issues.

It has a comparatively larger field of view (FOV) than TEM, allowing visualization of a larger area.

For applications where both SEM and TEM can be used, SEM is more cost-effective, with TEM analyses typically costing around 3 to 5 times more.

Ideal applications of TEM

TEM is a powerful tool for looking inside a sample. Key industries where TEM is used include nanotechnology, semiconductors, materials science, and electronics. When combined with negative staining or cryo preparation, TEM can also be used to image biological systems such as liposomes. In particle size analysis, it is typically applied to nanoparticles with a diameter of <50 nm. Larger particles can be imaged too, but SEM might be more practical.

TEM offers much higher magnification and resolution than SEM, but the FOV is smaller, so only a small part of the sample can be visualized.

A TEM image is a 2D projection, and the internal structures are viewed in a flattened view, making it sometimes hard to fully grasp the nature of the sample.

All electron microscopy services in one place

Measurlabs offers both SEM and TEM imaging, as well as EDX, EELS, EBSD, SAED, focused ion beam (FIB), and broad ion beam (BIB)-SEM. Our experts can also assist in selecting the most appropriate technique or techniques for inspecting your sample. You can contact us through the form below to discuss your analysis needs and to request a quote for your material.