Hande Güneş

PhD, Chemical Reaction Engineering

Inorganic Materials

Hande Güneş works at Measurlabs as a team lead and testing expert specializing in inorganic materials and powders. She considers the manipulation of materials at the atomic level to produce advanced technological solutions to be one of the most rewarding parts of the work, which is why she handles the bulk of Measurlabs’ nanomaterial characterization projects.

Hande holds a PhD in chemical engineering from Koç University in Turkey, where she focused on studying heterogeneous catalysis. Before joining Measurlabs, Hande worked on catalytic converters and emissions in the automotive industry and on indoor air quality solutions in the household appliances industry. The development of innovative solutions in these industries is one of her key professional interests.

Academic publications

Hande has co-authored several scientific publications on topics including nanocomposites and Pichia pastoris fermentation. Examples include:

Oxygen transfer as a tool for fine-tuning recombinant protein production by Pichia pastoris under glyceraldehyde-3-phosphate dehydrogenase promoter in Bioprocess and Biosystems Engineering

A Remarkable Class of Nanocomposites: Aerogel Supported Bimetallic Nanoparticles in Frontiers in Materials

Preparation of Pt/Al2O3 and PtPd/Al2O3 catalysts by supercritical deposition and their performance for oxidation of nitric oxide and propene in Catalysis Today

Hande’s latest articles in our blog

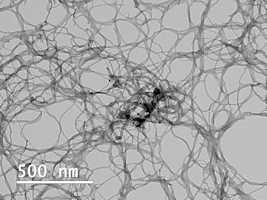

SEM vs TEM: How to choose the most suitable electron microscopy technique for your application

Scanning electron microscopy and transmission electron microscopy are both powerful techniques for high-resolution imaging, but they have some key differences.

Keep reading >

Powder characterization: techniques and applications

Key powder properties to be determined include particle size and shape, surface morphology, density, porosity, and flow properties.

Keep reading >

Summary of EFSA guidelines for assessing the safety of nanomaterials in food – which tests are needed?

In addition to engineered nanomaterials, conventional food products may need testing to prove they do not contain nanoparticles or have nanoscale properties.

Keep reading >