ToF-ERDA

Time-of-flight elastic recoil detection analysis (ToF-ERDA) is a quantitative material analysis method that gives concentrations of elements and their depth profiles in a sample. With ToF-ERDA, it is possible to detect all elements and distinguish between different isotopes of hydrogen.

What is ToF-ERDA used for?

Time-of-flight-elastic recoil detection analysis (ToF-ERDA), also known as elastic recoil detection (ERD), elastic recoil scattering (ERS), and forward recoil spectrometry (FRS), is an ion beam analysis (IBA) technique that is used to determine the elemental concentrations in thin-layer materials.

ToF-ERDA can detect all elements as well as different isotopes of hydrogen. It measures the concentration of each element within a sample as a function of depth, generating an elemental depth profile of the sample's surface. Detection limits between 0.1 and 0.5 atomic percent and depth resolutions of 5–20 nm are usually achieved. Surface layers with 20–500 nm thickness can be characterized with ToF-ERDA. To get reliable results, the sample must have a flat surface and roughness of less than 10 nm.

ToF-ERDA is most commonly used to determine the elemental depth profiles of thin films (metal oxides, nitrides, metals, etc.) on typical substrates, such as silicon (Si), gallium nitride (GaN), silicon carbide (SiC), gallium arsenide (GaAs), or indium phosphide (InP). The technique is handy when developing new thin film deposition methods or optimizing existing processes to understand how changes in the deposition parameters affect the elemental composition of the resulting thin films.

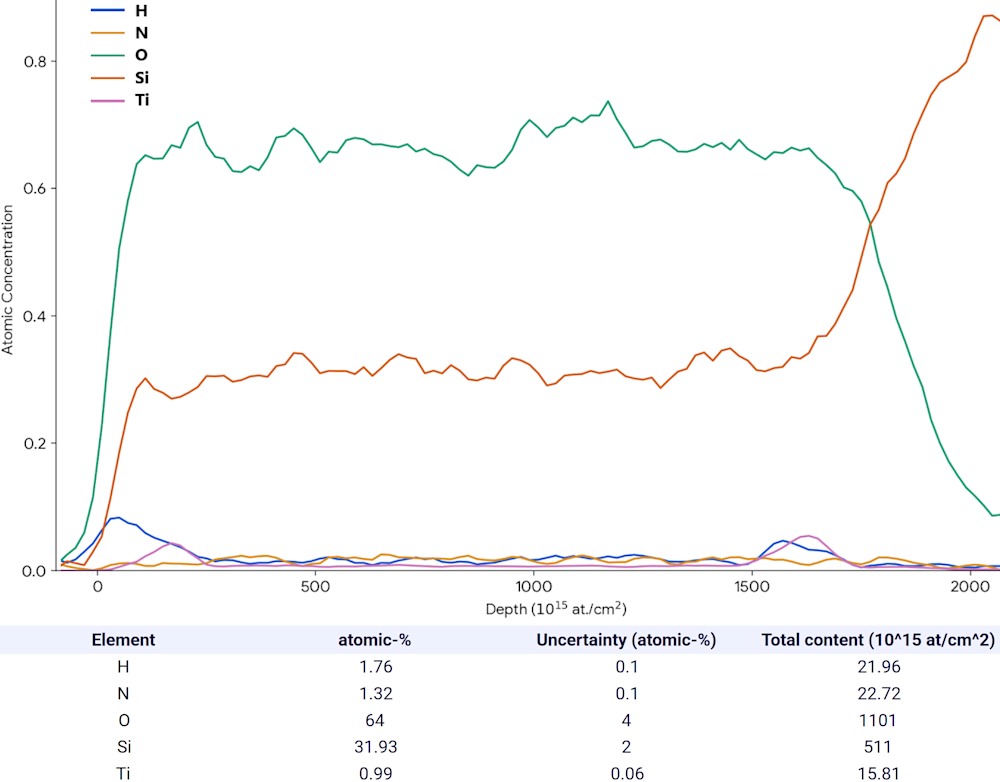

Below (Figure 1) is an example of ToF-ERDA results with elemental depth profiles and average elemental concentrations presented. For further details, see our example report for ToF-ERDA measurement.

ToF-ERDA is practically the only characterization technique that offers precise and cost-efficient hydrogen quantification simultaneously with quantifying the main components of thin films. The method is inherently quantitative when thin film samples on typical substrates are analyzed, so reference samples are not needed to achieve quantitative results.

What are the limitations of ToF-ERDA?

To get reliable results, the sample must have a flat surface and roughness of less than 10 nm. The detection limit is 0.1–0.5 atomic percent. A more sensitive method, such as SIMS, is needed to detect smaller concentrations. Only inorganic samples are suitable for ToF-ERDA analysis because the heavy ion beam damages organic samples.

How does Tof-ERDA work?

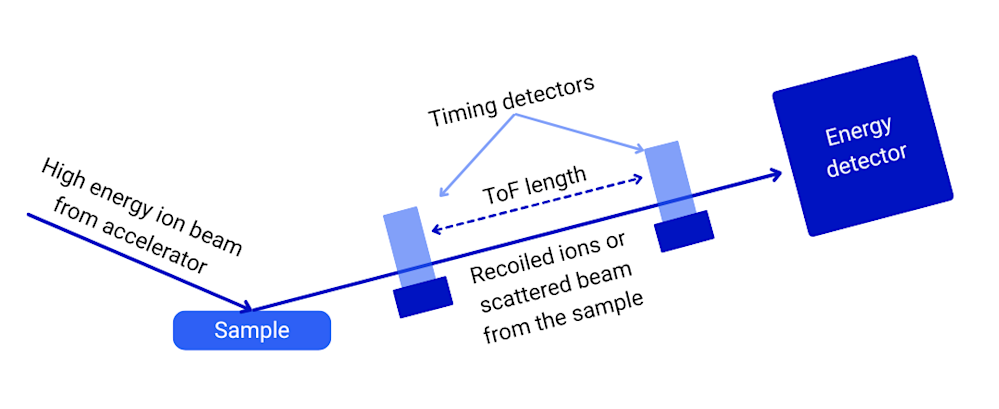

ToF-ERDA uses a heavy ion beam (such as Cl, I, Au) with energies typically ranging from 20 to 40 MeV. The energetic ion beam is directed at the sample at a known angle. The beam ionizes the sample atoms, and the ions from the sample surface layers recoil in a forward direction. Recoiled ions are then detected.

In ToF-ERDA, the recoil ion's energy and time of flight are measured simultaneously (Figure 2). Recoiled ions are typically detected with two timing detectors and an energy detector. Filters are used to separate electrons from recoil ions. Time-of-flight is measured with the timing detectors over a fixed distance. The energy detector distinguishes the different masses of the ions. Conversion of time/energy spectra is used to create a depth profile by using the known relationship of energy loss by a unit of length of the ions in the sample.

Alternative ERDA-technique: LI-ERDA

While the above-described ToF-ERDA involving a heavy incident ion beam is the most common one applied in modern materials research due to its capability to detect numerous elements simultaneously, other modifications of ERDA have also been developed and used for specific purposes. Most notable adaptation is light incident ion ERDA (LI-ERDA or Foil-ERDA), which is performed using a relatively low energy (0.2-2 MeV) helium ions as the incident ion beam to make the method more specific for hydrogen isotopes. The sensitivity towards hydrogen is increased further by using a Mylar range foil in front of the detector to block scattered heavy incident ions while allowing light recoiled target atoms to pass through.

The LI-ERDA setup enables increased depth resolution compared to normal ToF-ERDA (down to ~1 nm in certain applications) and detection limits in the range of 0.01 atomic percent. The downside of LI-ERDA is that it does not allow simultaneous detection of elements other than hydrogen and its isotopes, as ToF-ERDA with heavy incident ions does.

Need an analysis?

Measurlabs offers high-quality ToF-ERDA measurements and other thin film and semiconductor analyses with competitive prices and short turnaround times, even for large sample batches. Available techniques include SIMS, RBS, XPS, and others. You can request a quote using the form at the bottom of the page – we will get back to you within one business day.

Method Expert

Suitable sample matrices

- ALD, CVD, PVD or similar thin films

- Optics

- Semiconductors

- Thin films depositted on Si, GaN, SiC, GaAs or InP wafers

- Metal oxides, nitrides, metals, etc

Ideal uses of ToF-ERDA

- Elemental analysis and depth profiling of thin films

- Profiling light elements, such as H, B, C, N and O, in thin films

Ask for an offer

Fill in the form, and we'll reply in one business day.

Have questions or need help? Email us at info@measurlabs.com or call our sales team.

Frequently asked questions

Measurlabs offers a variety of laboratory analyses for product developers and quality managers. We perform some of the analyses in our own lab, but mostly we outsource them to carefully selected partner laboratories. This way we can send each sample to the lab that is best suited for the purpose, and offer high-quality analyses with more than a thousand different methods to our clients.

When you contact us through our contact form or by email, one of our specialists will take ownership of your case and answer your query. You get an offer with all the necessary details about the analysis, and can send your samples to the indicated address. We will then take care of sending your samples to the correct laboratories and write a clear report on the results for you.

Samples are usually delivered to our laboratory via courier. Contact us for further details before sending samples.