Grazing incidence X-ray diffraction

Grazing Incidence X-ray Diffraction (GI-XRD) is a specialized X-ray diffraction (XRD) technique used to identify the phase(s) present on thin films and coatings and to provide information on the crystallinity, crystallite size, lattice paraments and strain of the phase.

Some of our GI-XRD services

XRR + GI-XRD of thin films

GI-XRD of thin films

Prices excluding VAT.

What is grazing incidence X-ray diffraction?

Grazing incidence XRD (GI-XRD) is a modification of the X-ray diffraction (XRD) analytical method. With XRD, the crystalline phases present in a sample can be identified and their crystallinity, crystallite size, lattice parameters, and strain of the phases can be determined.

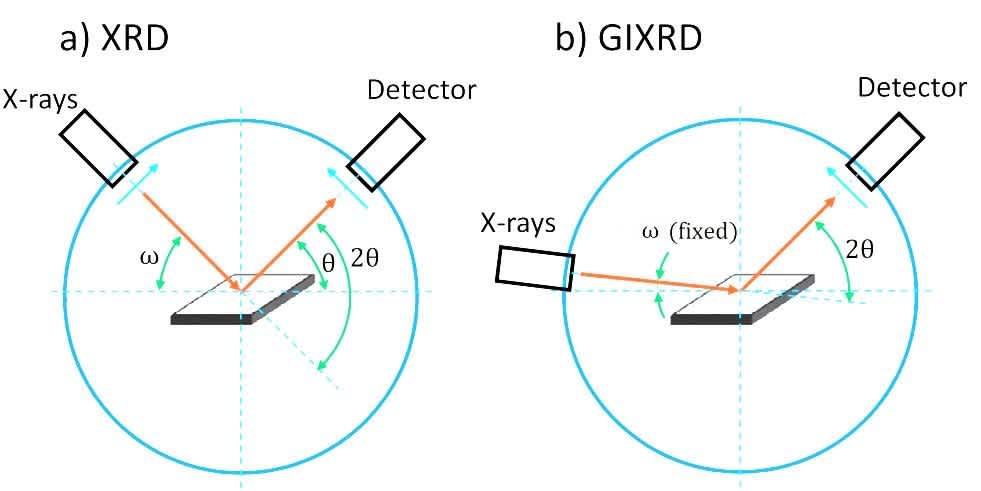

When X-ray diffraction (XRD) analysis is performed on thin films or coatings (1–1,000 nanometers thick) using conventional scanning parameters, the surface layer typically produces a weak signal, while the underlying layers generate a much stronger response (Scenario a in the figure below). This imbalance makes it challenging to accurately examine the top layers with a conventional XRD setup. To overcome this, measurements can be conducted with the X-ray source positioned at a fixed, small grazing incidence angle relative to the sample (Scenario b in the figure below). This technique, known as Grazing Incidence X-ray Diffraction (GI-XRD), enhances surface sensitivity and allows for more precise characterization of thin films.

You can find more information about the working principles of XRD on our XRD method page.

What is GI-XRD commonly used for?

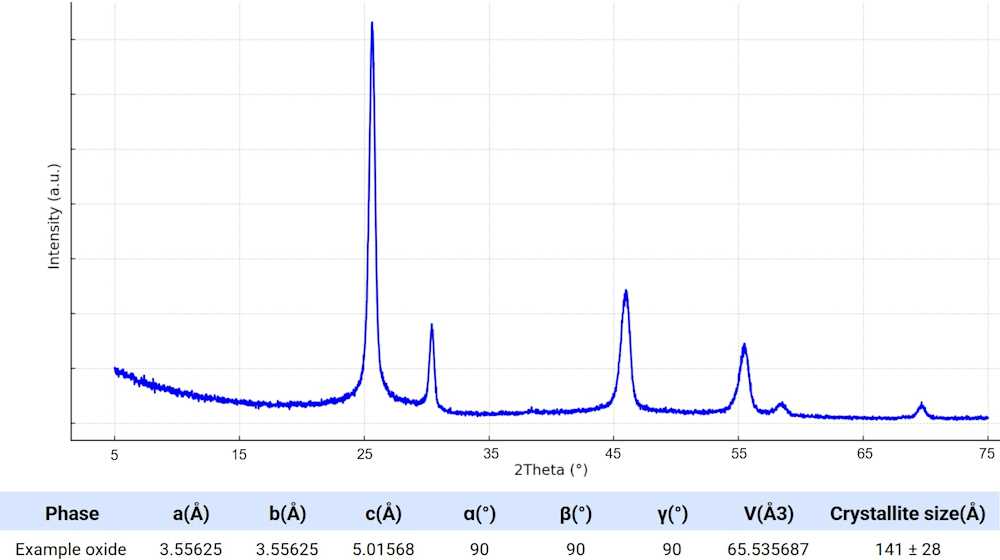

GI-XRD analysis reveals the phase(s) present in the sample and reveals its crystallinity, crystallite size, lattice parameters, and strain of the phase. GI-XRD is used to characterize crystalline thin films and coatings on solid substrates. When samples are subjected to GI-XRD analysis, a diffractogram and the associated structural data are obtained (see figure below and this example report).

GI-XRD is widely used by thin film and coatings manufacturers when they are developing new manufacturing techniques and need information on the crystalline properties of the materials produced. The most common use case for GI-XRD is the characterization of thin films (both inorganic and organic-hybrid) deposited on typical substrates, such as silicon (Si), gallium nitride (GaN), silicon carbide (SiC), gallium arsenide (GaAs), or indium phosphide (InP).

The method can also be used to study the effect of different surface modifications on the above-mentioned bare wafers. Other common use cases include the identification of unknown coatings and thin films, as well as investigating the effect that certain processing conditions have on coatings.

Suitable samples and limitations of GIXRD

GIXRD is best suited for the characterization of thin and smooth films and coatings. As a rule of thumb, samples with thicknesses ranging from just a few nanometers up to a micrometer with less than 10 nm RMS surface roughness are best suited for GI-XRD analysis. Thicker and rougher samples can also be analyzed, but the quality of the data tends to weaken when the thickness and roughness increase.

Only samples consisting of crystalline matter are suitable for detailed GI-XRD analysis, as amorphous matter yields practically no signals in GI-XRD. However, GI-XRD is sometimes intentionally used to examine amorphous thin films or coatings, as it provides a clear demonstration of their lack of crystallinity.

Samples containing many different crystalline components are difficult to analyze with GIXRD, as the diffractograms tend to be very complex, and it may be impossible to determine the crystalline parameters. When a layer of unknown material is to be identified, the layer should be homogeneous, or its composition should be consistent. A successful identification of an unknown material also requires it to exist in a reference data library.

How to properly adjust the incident angle of the X-rays?

In GI-XRD, the incident angle of the X-ray beam hitting the sample is adjusted relative to the critical angle of the reflected X-rays in the same way as in X-ray reflectivity (XRR), with which the structural properties of thin films can be determined. The critical angle of the reflected X-ray beam is unique for every material and is generally very small.

The higher the incident angle relative to the critical angle of the material, the deeper the X-rays go down into the material. Therefore, if the incident angle of the X-rays rises above the critical angle, the depth of the penetrating X-rays increases rapidly. When the incident angle is smaller than the critical angle, the X-rays penetrate the sample only to a depth of a few nanometers.

The surface sensitivity of GIXRD

The critical angle phenomenon enables grazing incidence XRD to measure the crystal structure of thin films and coatings by using small incident angles of the X-ray beam. Below the critical angle of the surface material, only an evanescent wave of the reflected X-rays is established for a short distance, and the wave is exponentially damped. Therefore, the reflections in the diffraction pattern are only coming from the surface structure in GI-XRD.

The incident angle is usually chosen to be slightly above the critical angle of the material to obtain a total reflection of the whole surface layer. Still, penetration of the X-ray beam into the bulk material is prevented and limited only to the surface layer, making the diffraction phenomenon surface sensitive. Because the overlapping peaks in the diffractogram coming from different depths of the sample are avoided with GI-XRD, the examination of thin surface films in film stacks is much easier.

GI-XRD also amplifies the weak diffraction signal coming from ultra-thin films and thus optimizes the intensity of the reflected X-rays. In conclusion, GI-XRD is a method that combines the best of two techniques: the analysis of crystal structure (XRD) and the examination of thin films (XRR).

GIXRD under non-ambient conditions

Grazing incidence XRD (GI-XRD) can be performed under normal (ambient) or controlled (non-ambient) conditions. In non-ambient GIXRD (NA-GI-XRD), the sample is analyzed while being subjected to specific environmental changes, such as variations in temperature, pressure, humidity, gas composition, mechanical stress, or electromagnetic fields.

Modifying these parameters in NA-GI-XRD leads to structural changes in the material, which can be observed in real time. This technique is useful for studying transformations that occur during processes like operation, heat treatment, calcination, sintering, hydration, and dehydration.

One widely used NA-GI-XRD technique is high-temperature XRD (HT-GIXRD), which helps investigate phase transitions, decomposition reactions, and the material's behavior at elevated temperatures. Certain instruments enable temperature-programmed experiments, where the temperature is gradually increased while continuously recording XRD data, allowing researchers to monitor structural evolution under heat exposure.

Measurlabs offers NA-GIXRD under a wide variety of different conditions.

Looking for GIXRD analyses?

Measurlabs offers laboratory testing with GI-XRD and NA-GI-XRD for thin films and bare wafers. A wide variety of different non-ambient conditions are available, such as the commonly used high-temperature XRD (HT-GI-XRD). We handle even large sample batches efficiently, and you can place new orders with just a few clicks in our customer portal.

Get in touch with our experts using the form below to get an offer for all the thin film and wafer analyses your team needs.

Method Expert

Suitable sample matrices

- ALD thin films

- CVD thin films

- PVD thin films

- Thin films on Si, GaN, SiC, GaAs and InP substrates

- Semiconductors

- Optical materials

- Coatings

Ideal uses of GI-XRD

- Examination of crystalline properties of thin films and coatings

- Material identification

- Quality control

- Failure and defect analyses, such as internal stress measurements

- Optimization of production processes

Ask for an offer

Fill in the form, and we'll reply in one business day.

Have questions or need help? Email us at info@measurlabs.com or call our sales team.

Frequently asked questions

Measurlabs offers a variety of laboratory analyses for product developers and quality managers. We perform some of the analyses in our own lab, but mostly we outsource them to carefully selected partner laboratories. This way we can send each sample to the lab that is best suited for the purpose, and offer high-quality analyses with more than a thousand different methods to our clients.

When you contact us through our contact form or by email, one of our specialists will take ownership of your case and answer your query. You get an offer with all the necessary details about the analysis, and can send your samples to the indicated address. We will then take care of sending your samples to the correct laboratories and write a clear report on the results for you.

Samples are usually delivered to our laboratory via courier. Contact us for further details before sending samples.