Water vapor transmission rate

Water vapor transmission rate (WVTR) testing determines how well a material holds moisture, also called the barrier effect. WVTR is an important parameter in the product development of materials that must withstand different moisture levels at varying temperatures, such as construction materials and packaging for food, cosmetics, and medical equipment.

Some of our WVTR testing services

Water vapor transmission rate (WVTR) of plastic films and sheeting

Water vapor transmission rate (WVTR) of packages

Water vapor transmission rate (WVTR) of paper and board

Water vapor transmission rate (WVTR) of textiles

Water vapor transmission rate (WVTR) of ultra-high barrier films and sheetings

EN 12086: Water vapor transmission properties of thermal insulation products

Prices excluding VAT.

What is the water vapor transmission rate?

Water vapor transmission rate (WVTR) represents the amount of water vapor that passes through a material or substance over a set period of time. Data received through a WVTR analysis is typically presented in g/m2 per day (the mass of water that passes through a one square meter area in 24 hours), as illustrated in this example report: WVTR and OTR of plastic films.

What is WVTR testing used for?

The water vapor transmission rate is an important variable in materials that are used in wet environments. In food contact materials, an effective moisture barrier keeps the product fresh and prevents it from gathering mold and mildew. Another important variable in food packaging testing is the oxygen transmission rate, which measures the material's barrier effect against oxygen.

A moisture barrier is crucial in the opposite case as well: when packing liquids, it is important to ensure the product does not leak through the material and thus get exposed to outer threats. In addition to food, this also applies to products like cosmetics and their packaging solutions.

In construction material applications, WVTR and moisture barriers are essential factors in wet rooms and outdoor solutions. For the same reason as in food packaging, moisture must be kept out to maintain the quality of buildings and building materials.

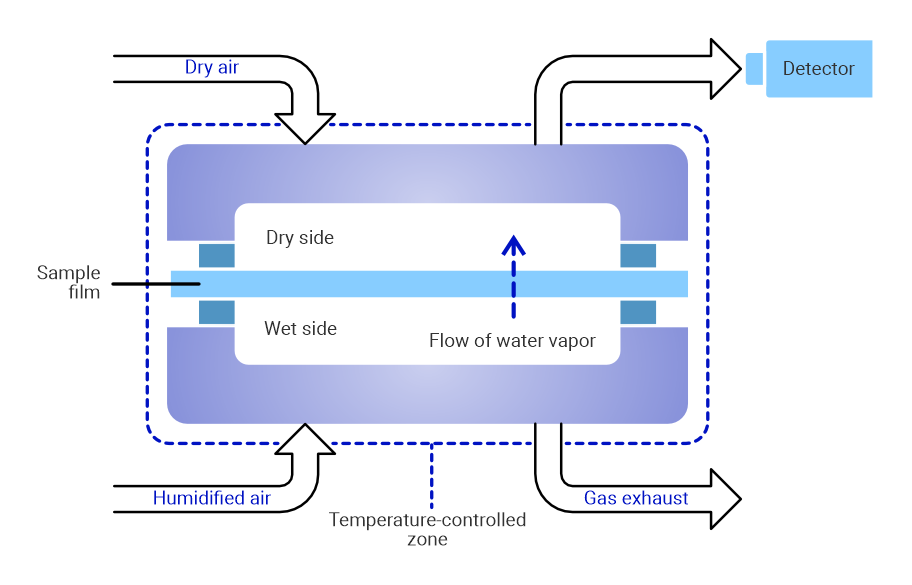

How is the water vapor transmission rate measured?

Different materials require different measurement techniques to get the most accurate WVTR results. Materials with weak barriers (that let through a lot of moisture) can be measured with a gravimetric technique, while materials with good barriers (that don't let through a lot of moisture) should be analyzed with humidity sensors or infrared sensors.

It is also important to make the testing conditions similar to the environment where the material will be used. This includes tuning the measurement temperature and relative humidity to simulate the intended real-world conditions. Measurlabs' experts always ensure that the measurements are conducted in the correct conditions so that the test results correspond to the real usage environment of your materials.

Need WVTR analyses?

Measurlabs offers high-quality WVTR, OTR, and other barrier testing services. Our experts can also help select the appropriate testing conditions to ensure the analysis gives you meaningful insights. Contact us using the form below to request a quote for your project – and remember to specify the number of samples, as volume discounts are often available for large or recurring testing needs.

Suitable sample matrices

- Coatings, such as wax, cellulose, polymers

- Foils

- Plastic films

- Fabrics

Industries where WVTR testing is typically needed

- Food contact materials

- Packaging materials

- Construction materials

- Textiles

Ask for an offer

Fill in the form, and we'll reply in one business day.

Have questions or need help? Email us at info@measurlabs.com or call our sales team.

Frequently asked questions

WVTR is commonly used for food contact materials, construction materials and packaging materials, in addition to any other kind of materials that are exposed to moisture or water.

WVTR measurement is carried out at a chosen temperature and moisture. The conditions must be chosen to represent the intended use. The measured surface needs to be free from scratches and other defects, as they allow the gases to pass through. The surfaces need to be smooth so that an effective sealing can be achieved.

WVTR is suitable for different coatings, such as wax, cellulose and polymers, foils, plastic films, and fabrics. Anything from sausage casing to technical sportswear, and more.

Measurlabs offers a variety of laboratory analyses for product developers and quality managers. We perform some of the analyses in our own lab, but mostly we outsource them to carefully selected partner laboratories. This way we can send each sample to the lab that is best suited for the purpose, and offer high-quality analyses with more than a thousand different methods to our clients.

When you contact us through our contact form or by email, one of our specialists will take ownership of your case and answer your query. You get an offer with all the necessary details about the analysis, and can send your samples to the indicated address. We will then take care of sending your samples to the correct laboratories and write a clear report on the results for you.

Samples are usually delivered to our laboratory via courier. Contact us for further details before sending samples.