The European Commission published a proposal for a new Packaging and Packaging Waste Regulation (PPWR) in November 2022 to address the environmental impacts of the packaging industry. After more than two years and several rounds of changes to the original proposal, Regulation (EU) 2025/40 was published in the Official Journal of the European Union on the 22nd of January 2025.

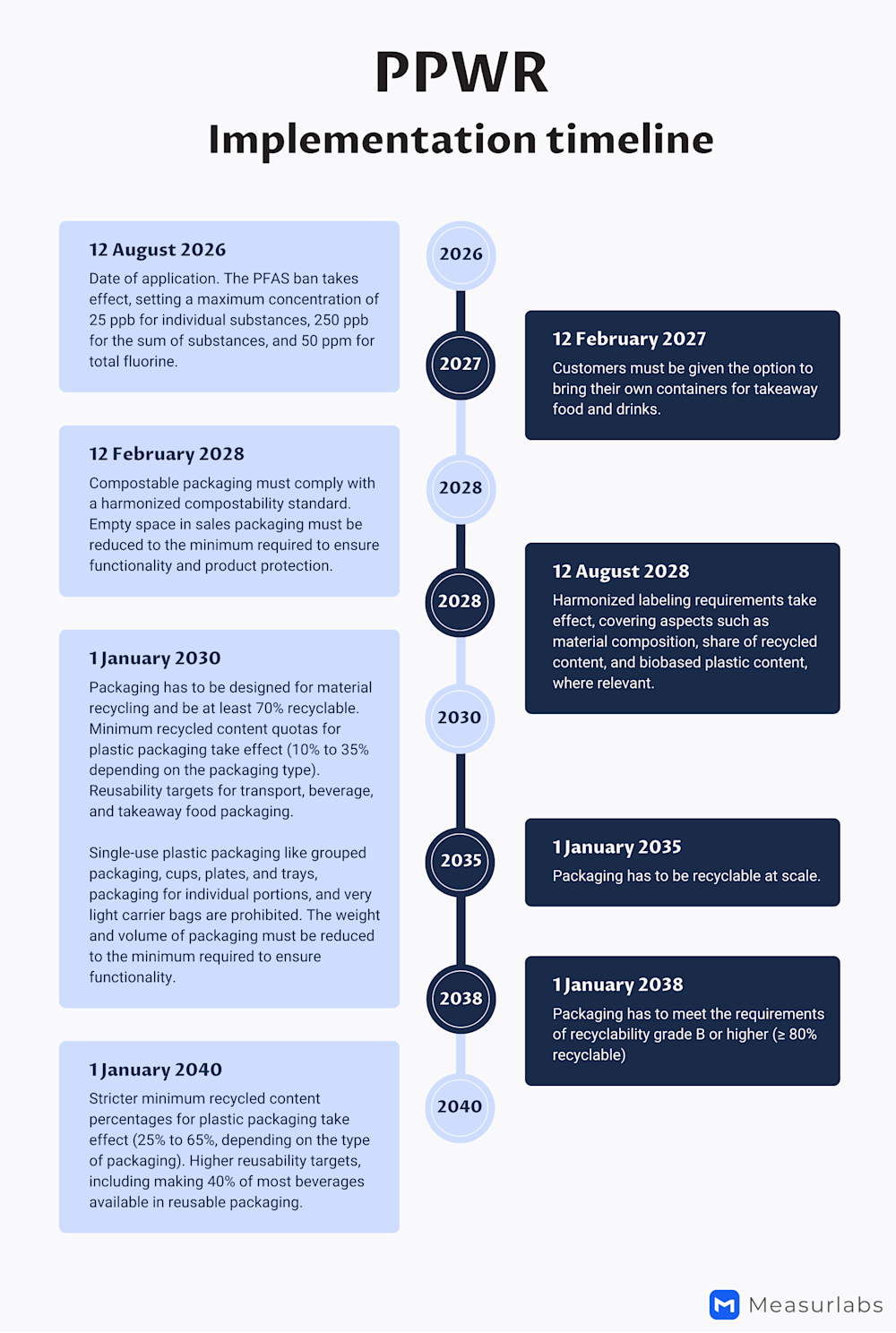

The PPWR entered into force in February 2025 and applies from the 12th of August 2026, introducing several new requirements for the types of packaging that can be placed on the EU market.1

What will the requirements be under the new PPWR?

The original PPWR proposal included ambitious reuse targets that were largely dropped after facing scrutiny from the industry. In its final form, the PPWR places a larger emphasis on recyclability and the reduction of unnecessary packaging, even though some reuse targets remain. Some of the key requirements are outlined below.

Design for recyclability

One of the core requirements of the PPWR, recyclability in an economically viable manner, will be enforced through the introduction of recyclability grades that packaging materials must meet. By 2030, packaging should meet the criteria for recyclability grades A, B, or C. Grade C materials will be phased out by 2038, after which only grade A and B packaging can be placed on the market. The main factor determining the recyclability performance grade will be the percentage (by weight) of the packaging unit that can be recycled:

Grade A: ≥ 95% recyclable

Grade B: ≥ 80% recyclable

Grade C: ≥ 70% recyclable

The specific criteria for assessing recyclability will be introduced through delegated acts by January 1st, 2028. The parameters considered will include the separability of components in multi-material packaging, the efficiency of sorting and recycling processes, and the quality of the recyclate, which should be sufficient to substitute for virgin materials in the production of new packaging.2

Recycled content quotas

The PPWR introduces minimum recycled content quotas for plastic packaging, including food contact materials. In the future, the average recycled content of plastic packaging produced at a manufacturing plant in one year will need to match or exceed the following:

30% for single-use plastic beverage bottles by 2030 and 65% by 2040

30 % for other contact-sensitive packaging made primarily from PET by 2030 and 50 % by 2040

10% for contact-sensitive packaging made from other plastics by 2030 and 25% by 2040

35% for other plastic packaging by 2030 and 65% by 2040

Increasing the use of recycled plastic in food-grade packaging will require increased investments in research and development of recycling technologies, as most recycled plastic is currently not considered safe for food contact use. The PPWR does acknowledge this by prioritizing safety over recycled content in cases where they come into conflict. This is reflected in an exemption for plastic food packaging in cases where the amount of recycled content would lead to non-compliance with existing food contact material regulations. Other high-risk applications, such as medical device and pharmaceutical packaging, are also exempted.3

Minimized presence of substances of concern

The PPWR introduces additional requirements for the chemical safety of packaging materials, especially when they come into contact with food. The most notable change is a ban on per- and polyfluorinated alkyl substances (PFAS) in food contact materials from the 12th of August 2026. To comply with the PPWR, food packaging must not contain PFAS in concentrations exceeding the following limits:

25 ppb for any individual PFAS measured through targeted analysis

250 ppb for the sum of targeted PFAS

50 ppm for total organic fluorine as an indicator for total PFAS.

Regarding other substances of concern, the PPWR retains the restriction on heavy metals as specified in the previous Packaging Directive 94/62/EC. This means the maximum concentration levels for lead, cadmium, mercury, and hexavalent chromium will remain at 100 mg/kg by weight, although they may be lowered in the future.4

The PPWR also requires companies to seek to minimize "the adverse impact on the environment due to microplastics".5 However, there is currently no concrete compliance criteria for this.

Reduction of unnecessary packaging

The PPWR sets out to reduce packaging waste by limiting the volume and weight of packaging to the minimum required to ensure functionality and recyclability. This includes capping the empty space ratio to a maximum of 50% by the start of 2030 and introducing a ban on characteristics aiming to increase perceived volume, such as double walls and false bottoms.6

As a part of the packaging reduction effort, certain single-use packaging will be banned from 2030. These include very light plastic bags and packaging for miniature toiletries, unprocessed fruit and vegetables, and individual portions of sauces, condiments, sugar, and other similar food products.7

Reuse targets

To encourage the replacement of single-use packaging with reusable alternatives, the PPWR sets reuse targets for transport and beverage packaging. This includes an obligation for beverage distributors to make at least 10% of products available in reusable packaging by 2030 and 40% by 2040. In addition, takeaway food and beverage distributors will have to offer consumers the option to bring their own containers, and they should aim to sell 10% of products in reusable packaging by 2030.8

Requirements for compostable packaging

The PPWR limits the use of compostable and biodegradable packaging to applications where biodegradability brings about genuine benefits (e.g., tea bags, coffee filters, and sticky labels for fruit and vegetables). Such materials must decompose safely and effectively in typical compost conditions, as demonstrated by data from compostability testing conducted according to harmonized standards.

As there is currently no harmonized standard for home compostability, the Commission will request European standardization organizations to create one. The existing industrial compostability standard EN 13432 will also be revised.9

Packaging testing to assess PPWR compliance

The requirements the PPWR sets for packaging will take effect after an 18-month transition period in August 2026, apart from cases where a later date is specified in the regulation. While this gives packaging manufacturers a fair amount of time to prepare for the regulation, taking proactive steps toward compliance now helps avoid costly last-minute changes to production processes later.

Our laboratory testing services can facilitate the development of PPWR-compliant packaging solutions. Some examples include:

Paper and board recyclability testing to ensure that fiber-based packaging can be recovered efficiently in standard paper mills.

PFAS testing to ensure concentrations do not exceed specified limits. See this example report: TOF & PFAS analysis for PPWR compliance.

Full range of food contact material tests to ensure that plastic packaging with recycled content, and other PPWR-compliant materials, also comply with EU food contact material regulations.

Re-usability testing for plastic food packaging to show that it should not be classified as single-use plastic.

Biodegradability and compostability testing to verify that compostable plastics can be disposed of through the bio-waste stream.

Testing of microplastic migration from packaging materials to measure emission levels in preparation for potential future thresholds.

You can inquire about these and additional testing options using the form below. Our experts typically reply to queries within one working day.

References:

1 Regulation (EU) 2025/40 on packaging and packaging waste. Entry into force and application date are specified in Article 71.

2 Design for recyclability requirements are outlined in Article 6 and recyclability classes in Annex II to the PPWR.

3 Recycled content targets are specified in detail in Article 7 of the PPWR.

4 Restrictions on substances of concern are outlined in Article 5.

5 See Article 5 (1) of the PPWR.

6 The rules on packaging minimization are specified in Articles 10, 24, and 25.

7 The full list of single-use packaging types to be banned is given in Annex V, along with exempted uses.

8 Reuse targets are outlined in Article 29 and takeaway sector refill obligations in Articles 32 and 33.

9 Rules for compostable packaging are outlined in Article 9 and Annex III.