Rheology testing

Rheology measures the flow of fluids and soft materials under specified types of stress. Rheological testing is an important part of quality control and product development in industries including food, building materials, polymers, pharmaceuticals, and cosmetics.

What is rheological analysis used for?

Rheological analysis is used to measure the flowing properties of fluids that do not have a constant viscosity independent of the stress applied to them. The way in which these so-called non-Newtonian materials flow in processes is of utmost importance when designing industrial processes or equipment.

A good example of this is the injection molding of plastics. During injection molding, the viscosity of the material must be low enough for it to flow freely into the molds. At the same time, manufacturers do not want to use excessive amounts of energy or heat in the molding process to avoid compromising material quality, making rheological measurements necessary to optimize the process.

How are rheological properties measured?

Rheological properties are usually tested using a rheometer, which is a device that measures the flow characteristics of the substance when it is subjected to stress. Rheometers come in two major categories: shear rheometers (also called rotational rheometers) apply shear stress and extensional rheometers extensional stress on the sample.

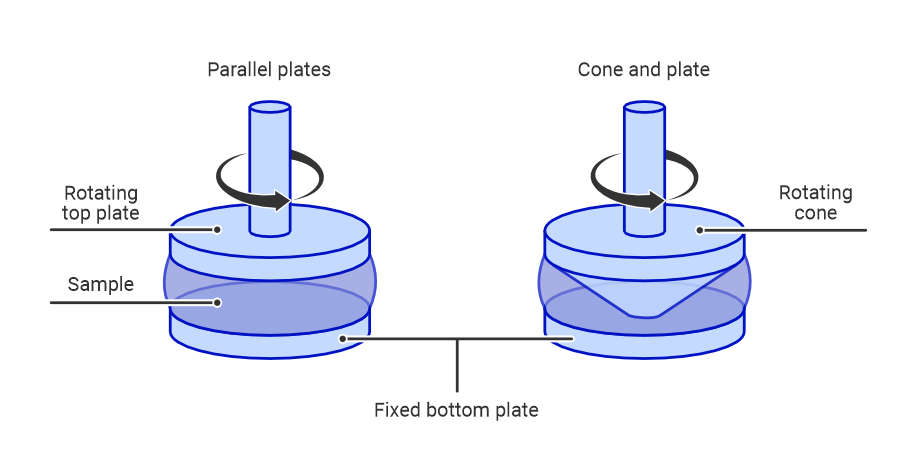

Shear/rotational rheometers include a metal spindle of a specified geometry that rotates at a set speed. The spindle is inserted into the substance to be tested and begins to rotate. The device then measures the resistance the substance puts on the spindle to prevent it from freely spinning. This data is used to calculate the resistance to flow, or viscosity, of the substance.

Typical rotational rheometry setups include plate-and-plate and cone-and-plate, but many other configurations may also be used, with the selection based on sample properties.

The way in which viscosity changes as a result of shear stress being applied helps divide fluids into shear-thinning and shear-thickening ones. Shear-thinning fluids experience a reduction in viscosity under high shear rates, while shear-thickening materials experience an increase in viscosity with higher shear rates.

What kinds of samples are suitable for rheology testing?

Examples of substances that rheology applies to include many "thick" liquids, such as glues, paints, oils, and foods such as honey, yogurt, and ketchup. Rheology testing can also be used to analyze substances with both liquid and solid properties under different conditions, such as concrete and many polymers.

Rheology vs. viscosity

Often the terms rheology and viscosity are used almost interchangeably. While they do refer to the same area of scientific research, they have slightly different meanings. ’Rheology’ refers to the science of how materials and substances deform and flow, whereas ‘viscosity’ is the measure of these properties. In other words, measuring viscosity is a form of rheological analysis, but rheology extends beyond just testing for viscosity.

Rheology with Raman spectroscopy

Rheological testing primarily provides data on the physical and mechanical properties of the sample, which means that another technique must be employed to gather information on the sample's chemical properties. Raman spectroscopy is sometimes used in conjunction with rheological analysis to provide simultaneous information on chemical structure and rheological properties.

Need an analysis?

At Measurlabs, we offer rheological laboratory analyses for various sample types, such as polymers, liquids, and suspensions. From tens to hundreds of samples, we ensure your analyses are handled on time, with the highest quality. Our testing experts are here to answer any questions you may have and do their best to accommodate specific requests about reporting or timelines. Contact us through the form below to request a quote and start the discussion with our team.

Suitable sample matrices

- Oils

- Adhesives

- Cement

- Polymers

- Thick liquid food products (e.g. ketchup, yoghurt, melted chocolate)

- Mud and sludge

Ideal uses of rheology testing

- Measuring the viscosity of polymers

- Evaluating the mechanical properties of oils

- Testing soft solid matter

- Quality control in the food industry

Ask for an offer

Fill in the form, and we'll reply in one business day.

Have questions or need help? Email us at info@measurlabs.com or call our sales team.

Frequently asked questions

Rheological properties are often measured when assessing the quality of construction materials like cement and paints, polymers, liquid pharmaceuticals, cosmetic products, and foods.

Measurlabs offers a variety of laboratory analyses for product developers and quality managers. We perform some of the analyses in our own lab, but mostly we outsource them to carefully selected partner laboratories. This way we can send each sample to the lab that is best suited for the purpose, and offer high-quality analyses with more than a thousand different methods to our clients.

When you contact us through our contact form or by email, one of our specialists will take ownership of your case and answer your query. You get an offer with all the necessary details about the analysis, and can send your samples to the indicated address. We will then take care of sending your samples to the correct laboratories and write a clear report on the results for you.

Samples are usually delivered to our laboratory via courier. Contact us for further details before sending samples.