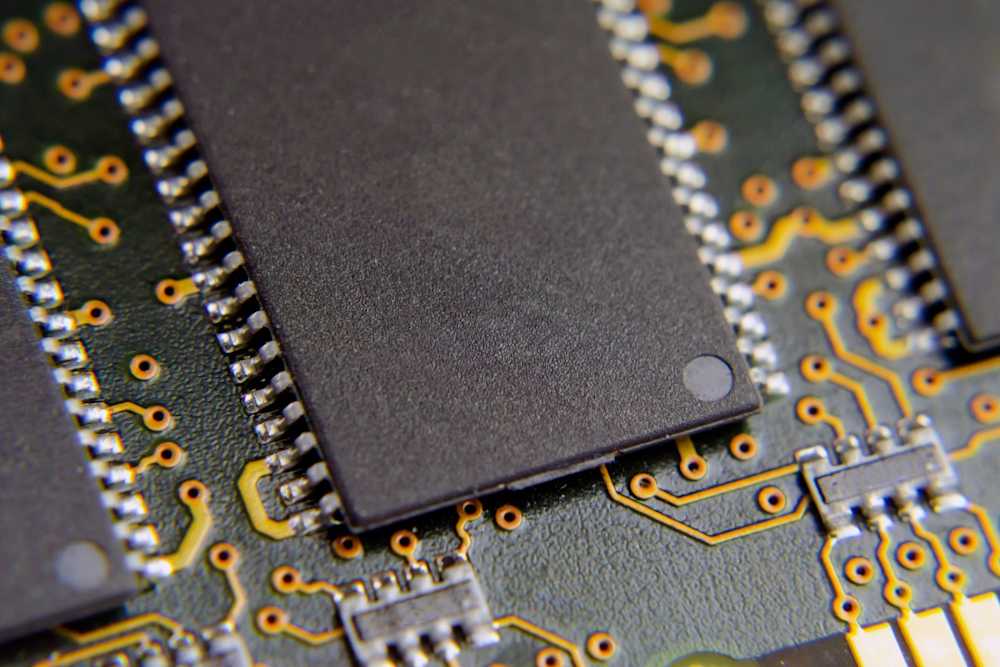

Semiconductor failure analysis has been a growing need in the field to improve the design, processing, and testing of devices. It enables the identification of problems with the device and the determination of their causes.

Failure analysis consists of a series of tests aimed at obtaining zero defect components in mass production. These can include electrical tests, such as thermal/photo emission analyses, electrical parameter checks, and switching timing control tests, as well as microscopy investigations for identifying further defects.

Types and causes of failure

All semiconductor failures fall under two main categories: parametric failure, which occurs when a device’s functional attributes are outside the desired specifications, and functional failure, which occurs when a device doesn’t perform its intended function.

Depending on the semiconducting device, failures can be visual, mechanical, thermal, or electrical. There can be many causes for device failure, originating from defects such as voids, stress, dopant disorders, impurities, and localized distortions.

Failure analysis techniques and their applications

Identifying fine defects requires very precise techniques to probe the surface and depth of semiconductor devices. Measurlabs offers a wide range of analyses to complement routine checks and help identify challenging failure sources. Some examples are presented below:

Scanning Electron Microscopy (SEM)

SEM is used to observe small defects, typically in the size range of 10 nm, on the surface of a device. In-depth analysis can also be done by investigating cross-sections of a device that can be prepared, for example, by Focused Ion Beam (FIB) or Broad Ion Beam (BIB). SEM can also be used for a general elemental composition analysis when combined with Energy-Dispersive X-ray Spectroscopy (EDS or EDX). Windowless EDX analyzer can provide a relative quantification of any element from boron upward in an amount above 0.1 - 1 wt.%. Examples of typical uses of SEM in semiconductor failure investigations include crack and void inspection, thickness conformity measurement, and particle identification.

Transmission Electron Microscopy (TEM)

TEM is used to investigate even smaller defects at sub-nm scale and can also be combined with EDX measurements to investigate elemental composition and diffusion. FIB is used to create a sample lamella thin enough to be analyzed (~ 100 nm). TEM allows a wide range of analyses, such as interface diffusion, dislocation, crystalline structure, and other fine defect inspections.

Scanning Acoustic Microscopy (SAM)

SAM is a non-destructive ultrasonic wave-based technique that can be particularly useful for semiconductor devices with multi-layer stacks. SAM provides 3D images of the structure and enables the analysis of full 300 mm wafers with µm resolution. It can be used to investigate cracks, voids, or adhesion/delamination. The main advantage of SAM is that the defects don’t need to be precisely localized before testing since the full sample structure is observed.

Fourier-Transform Infrared Spectroscopy (FTIR)

FTIR is a non-destructive technique used for composition studies. It can be used for compliance measurements and to measure the concentration of residual oxygen in Si wafers. More recently, FTIR has also found applications in emission analysis. It can detect analytes at ppm level and provide real-time measurements.

Choosing the right testing methods

A wide range of tests is needed for comprehensive failure analysis in the mass production of semiconductors. Measurlabs offers these tests from simple routine electrical measurements to more challenging investigations of defects with techniques most adapted to your needs.

Our testing experts can help you choose the best method based on your unique device architecture and research question. Contact us via the form below to request a quote, and we'll get back to you in one business day.