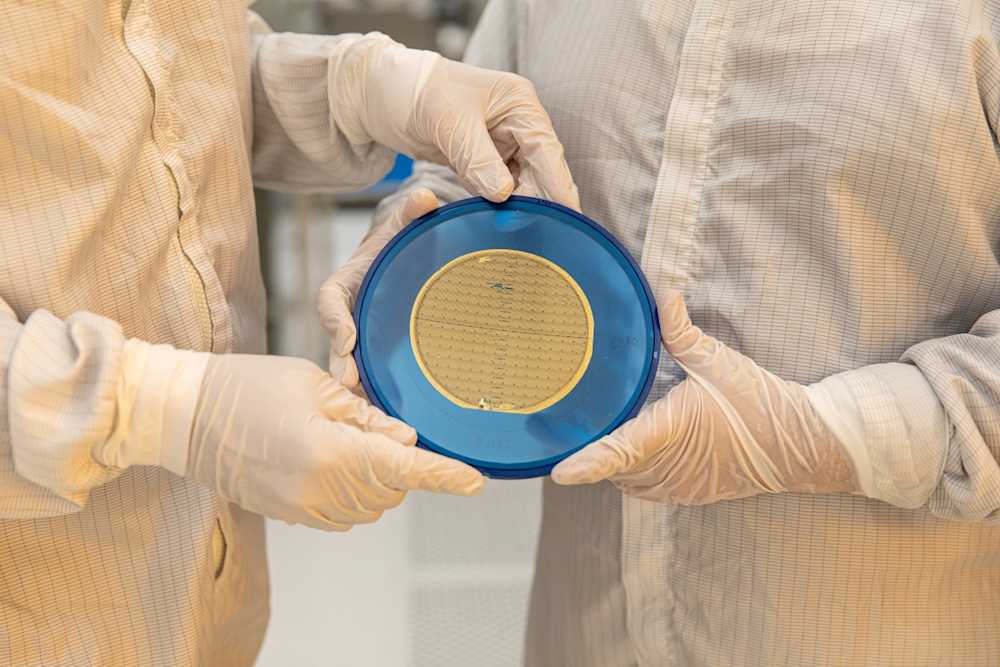

Low Noise Factory (LNF) designs and produces ultra-low-noise microwave amplifiers that are engineered to operate at cryogenic temperatures close to absolute zero. Founded in 2005 and headquartered in Gothenburg, Sweden, the company serves demanding fields such as space exploration, quantum computing, and radio astronomy.

With a complex multi-step manufacturing process and devices designed for extreme environments, Low Noise Factory places strong emphasis on precision and continuous process development. Measurlabs supports this work by providing advanced cross-sectioning and imaging services, allowing LNF to observe the tiniest nanometer-scale details about how their devices are constructed.

Guiding process development through high-resolution imaging

Low Noise Factory’s collaboration with Measurlabs began in early 2025, when Arsalan Pourkabirian, Head of the Semiconductor Devices Department, was searching for a long-term partner for routine FIB-STEM imaging of transistors.

“Consistent, high-resolution images of our transistor cross-sections let us detect process variations down to the near-atomic scale and make informed adjustments to the process,” Pourkabirian explains.

In addition to the imaging quality, the proximity of the service was a key factor in LNF’s decision to partner with Measurlabs.

“Not having to ship samples across the world is important for many of our customers,” notes Kalle Niiranen, Technical Account Manager at Measurlabs’ Inorganic Materials team. “For Low Noise Factory, we organized the measurements in Finland, but just as often, we use our extensive partner network to arrange analyses in other frequently requested locations, such as the USA or the UK.”

Reliable turnaround and clear communication

Measurlabs’ reliability has been central to the partnership. While the promised standard delivery time for FIB-STEM is two weeks, Low Noise Factory has typically received the results within 1–1.5 weeks. Reports and imaging data are easily accessible through the customer portal, which also supports two-way communication, enabling LNF to upload detailed sample preparation and analysis guidelines.

The exact methods for cross-sectioning and imaging were developed through discussions between the LNF team and Measurlabs’ experts.

“Finding the best way to handle these samples required some iteration, but we quickly established a workflow that works for both sides,” says Testing Expert Kamal Mundoli. “That collaborative approach is what makes the results consistent.”

A strong basis for expanding the collaboration

With routine imaging workflows now in place, the partnership is likely to expand in the future. One possibility is to supplement currently collected data with high-resolution TEM-EDX mapping, which provides elemental composition data at the nanometer scale, beyond what is achievable with the more conventional and widely available SEM-EDX technique.

By combining technical expertise, dependable delivery times, and effective communication, Measurlabs enables Low Noise Factory to advance process development and maintain the high performance required of its amplifiers.

“Having such a reliable partner helps us focus on refining our own processes, as we know that analyses will be performed on time and according to our exact specifications,” Pourkabirian concludes.