Contact angle measurement

Contact angle measurement is used to evaluate surface wettability, which is an important characteristic in the development of new hydrophobic materials, such as waterproof textiles, polymers, paints, and coatings.

- Fast turnaround times

- Personal service from method experts

- Competitive prices

- Result accuracy guarantee

What is contact angle measurement?

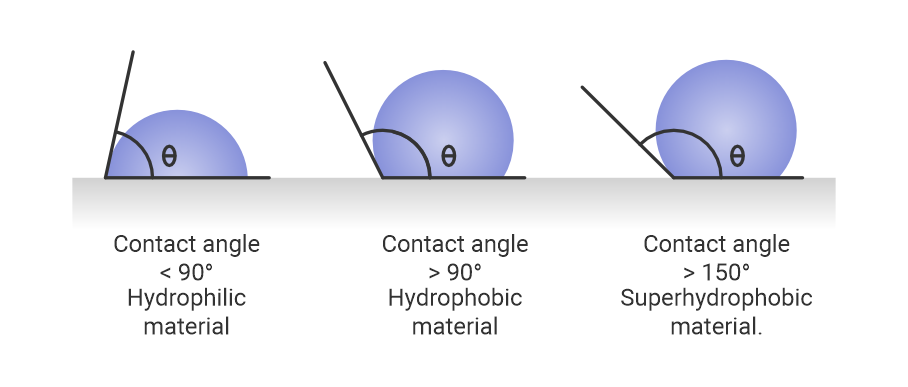

The contact angle is a value demonstrating the wettability of a solid material by a liquid. In the literature, materials with water contact angles between 0 and 90° are considered hydrophilic, between 90 and 150° hydrophobic, and above 150° superhydrophobic.

Why measure contact angle?

Wettability (hydrophilicity vs. hydrophobicity) is an important parameter in industries including paints, coatings, textiles, and construction materials. For example, self-cleaning materials and waterproof fabrics need to be analyzed with contact angle measurement to evaluate their performance.

How is contact angle measured?

Static contact angle measurement is the most common method that utilizes the sessile drop method. A contact angle goniometer and a high-resolution camera are used to capture an image of the drop sitting on the surface from the side view and measure the contact angle.

Alternatively, the dynamic contact angle can be measured. Dynamic contact angles are presented as receding and advancing angles, depending on the direction where the drop of liquid is moving on a tilted surface. The angle of contact where the drop begins its movement is referred to as the roll-off angle.

Which factors affect the contact angle?

Contact angle measurement is susceptible to different internal and external factors. For example, surface roughness, density, and relative moisture content can affect the eventual contact angle measurement results.

Contact angle measurement can also be affected by contaminants or static electricity. If the sample surface is rinsed and subsequently rubbed dry, static electricity can build up on the surface and alter the measurement results.

Sample requirements and preparation

To get the most accurate and reliable results from a contact angle measurement, it is necessary to prepare the samples with great care. A good practice is to clean and dry the sample material in such a way that it becomes as clean and neutral as possible. In repeated measurements, the same spot should never be used. Even with careful handling, cleaning, and drying, the sample will be affected by the placement of the drop, and subsequent measurements can produce inaccurate results.

Need a contact angle analysis?

Measurlabs offers contact angle testing services with fast results and competitive prices. We process even large sample batches with speed, precision, and quality, enabling you to get the insights you need without unnecessary delays. Reach out to us using the form below to request a quote and we will get back to you latest the next business day.

Suitable sample matrices

- Metals

- Ceramics

- Polymers

- Fabrics

- Coatings & paints

- Paper & board

Ideal uses of contact angle measurement

- Wettability

- Hydrophilic/hydrophobic properties

- Alterations in wettability with different treatments

- Surface energy

Ask for an offer

Fill in the form, and we'll reply in one business day.

Have questions or need help? Email us at info@measurlabs.com or call our sales team.

Frequently asked questions

Contact angle measurement can be used to understand the surface energy, wettability, and hydrophilic/hydrophobic properties of a material. It is often used in the paper-, board-, textile-, coatings-, and metallurgical industries.

Suitable sample materials include, for example, metals, ceramics, polymers, fabrics, coatings, paints, paper, and board.

Measurlabs offers a variety of laboratory analyses for product developers and quality managers. We perform some of the analyses in our own lab, but mostly we outsource them to carefully selected partner laboratories. This way we can send each sample to the lab that is best suited for the purpose, and offer high-quality analyses with more than a thousand different methods to our clients.

When you contact us through our contact form or by email, one of our specialists will take ownership of your case and answer your query. You get an offer with all the necessary details about the analysis, and can send your samples to the indicated address. We will then take care of sending your samples to the correct laboratories and write a clear report on the results for you.

Samples are usually delivered to our laboratory via courier. Contact us for further details before sending samples.